系列化高质量产品生产体制

开发、设计工序

利用电脑3维设计软件进行信息储存、分析和处理。设计时根据多方面的需求,考虑其安全性、耐

久性、共同性及永久性的特点,设计具有适应市场要求的新型产品。

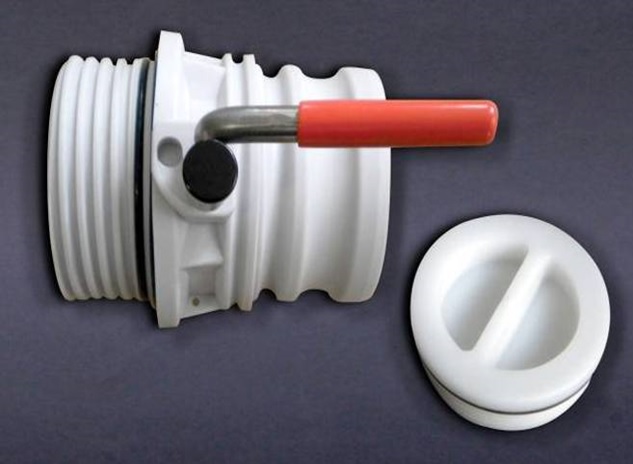

注塑工程

阀体的注塑技术是决定阀门质量的关健。因此,本公司在进行严格的选材后,利用先进的电脑注塑

机,应用长年积累的工艺经验和精湛技术,生产出值得高度信赖的注塑产品。

加工、装配工程

零部件的机械加工采用数控制CNC机床及线切割等设备,建立了快捷、保质、保量的生产体制。

试验、检查工程

广州铧劳机电设备有限公司对品质检查方面要求十分严格,采用多种不同方法,包括:化学成份分

析、非破坏性检查、机械强度测试及流量特性试验等。在最后品质检定过程中,用1.5倍压力全检

产品的压力要求及连接密封,保证阀门的高品质是广州铧劳机电设备有限公司向客户的承诺。

The Integrated production System

For the Supply of High Quality Products

Product Development and Design

Electronic data processing is applied to supply analog and digital data for the research, development and

design of all new products. Advanced systems applications help satisfy complex evaluation criteria for such

varied factors as marketability, functional advantages, safety, durability, product performance, component

interchangeability and maintenance ease.

Injection mould

Sophisticated injection mould techniques and experiences learned over the years are responsible for the

high quality of all shell materials of CD FLEXI-Valves, the pressure containing devices. Stringently selected

raw materials are mould into valve shells of high reliability. It is carried out by Injection Mould Machine.

Machining and Assembly

Highly automated machining and assembly shops systematically produce CD FLEXI-Valves of constant quality

in a steady supply for on-time delivery. It is carried out by CNC Lathes and CNC Wire Cut Machine.

Testing and Inspection

CD FLEXI-Valve Quality Control is supported by an elaborate network of test and inspection facilities that

include automated chemical analyzers, mechanical property testers, a wide variety of non-destructive

examination apparatus, and elaborate hydrodynamic testing system. Final performance evaluation is carried

out at 1.5 times pressure for all products of working pressure and connecting seal to ensure high-quality

valves.